Medical Device Consultancy Services

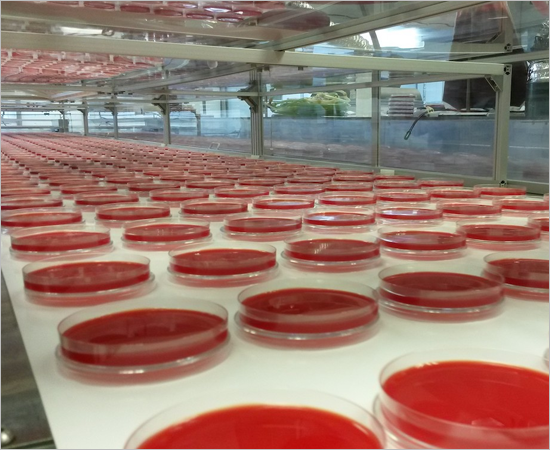

In recent times the uptake of Ready To Use Microbiology culture media products, the diversification of product formats and the expansion in manufacturing capabilities have all increased. Our consultants are trained in USFDA, SFDA, ISO 13485 In-vitro Medical device requirements. We have over 25 years of experience in Microbiology product manufacturing in USA, UK and Saudi Arabia and managed prestigious tenders in Gulf States.

The Consultant also partners with well maintained, veterinarian supervised sheep farm to draw sheep blood using specially designed harvesting bags and custom-made sheep blood collecting instruments. We have years of know-how on:

- Traceability and identification of the blood source

- Breed selection for donor animals

- Quality control testing methods before batch of blood release

- Setting up sheep farm to suit any geographical location

Benefits Of RTU Manufacturing Factories

- Cost reduction

- Productivity gains

- Control and consistency through Good Manufacturing Practice

- Introduction of new products in the market

- Create jobs locally to support the economy

- Reduction of costs associated with imports

- Facilitating regulatory conformance

What we can offer

Part 1: Consultation on the designing the Manufacturing Facility based on current guidelines floor plan and layout in compliance with ISO 13485 and FDA and GCC visit team

Part 2: Machines and Equipment for manual, semi-automated and automated for small scale and large-scale manufacturing

Part 3: Outsourcing Raw Materials with bulk price

Part 4: Consultation and negotiation of Petri dish, glassware, blood bags, Printing & Packaging Components

Part 5: Preparation Batch Manufacturing Records, work instructions, in-process control and traceability and recall documents

Part 6: Preparation of QC and QA Testing Methods

Part 7: Origination of Site Master File

Part 8: Validation and calibration Master Plan

Part 9: Product Catalogue, brochures and website designing recommendation

Part 10: Standard Operating Procedures (SOP) from raw material receiving to delivery in compliance with ISO and FDA

Part 11: Selecting and appointing logistics in compliance with FDA

Part 12: Consultation on Sheep Blood harvesting farm (Setting up the sheep farm, providing necessary sheep blood harvesting instrument for a reasonable price, training the staff for bulk sheep blood harvesting, pooling and processing the blood for production)

Part 13: Arrangements to set up a farm or contract this service with local farms

Part 14: Consultation and recommendations on animal welfare, selection of the right breed, selection of the correct feed

Part 15: Selection and offer of custom-made blood collecting accessories

Part 16: Outsourcing Blood collecting and blood pooling bags

Part 17: Staff training: how to select the right sheep by age, sex, weight, how to collect and how to process blood

Part 18: Setting up of small scale / mobile laboratory

Part 19: Origination of Standard Operation procedure and other documents

Part 20: Advice on Logistics for Storage and transportation system

What are the benefits of having local blood harvesting farms?

Animal blood is one of the most frequently used culture media ingredients. Around 40% of culture media products are supposed to contain blood. The shelf – life of animal blood is very short.

Due to the above reasons, the significant advantages in harvesting animal blood locally are:

- Availability of freshly harvested animal blood for production

- The cost of production will reduce by around 30%

Currently, imported sheep blood will cost more and is regularly faced with difficulties in importing and customs clearance delay, leading to prolonged stay in the airport and haemolysis and contamination. Customs duty is adding to the cost.